Table of Contents

Sustainable Food Production Through Vermicomposting | Report

Acknowledgements

The team deeply thanks Instituto Superior de Engenharia do Porto (ISEP) for providing their facilities during this semester. Furthermore, the team expresses their gratitude to the ISEP and European Project Semester (EPS) organizers and teachers who provided us with this enriching experience to be involved in a challenging project that allows us to grow personally and professionally.

Glossary

| Abbreviation | Description |

|---|---|

| B2B | Business to Business |

| B2C | Business to Customer |

| C-U | Control-Unit |

| EMC | Electromagnetic Compatibility |

| EPS | European Project Semester |

| EU | European Union |

| EUIPO | European Union Intellectual Property Office |

| FAQ | Frequently Asked Questions |

| GHG | Greenhouse Gas |

| IoT | Internet of Things |

| ISEP | Instituto Superior de Engenharia do Porto |

| LAN | Local Area Network |

| LCA | Life Cycle Assessment |

| LVD | Low Voltage Directive |

| OE | Order of Engineers |

| PBI | Project Backlog Item |

| PDCA | Plan-Do-Check-Act |

| PFC | Perfect Fit Client |

| PSS | Product Service System |

| RED | Radio Equipment Directive |

| RFID | Radio-frequency Identification |

| ROHS | Restriction of Hazardous Substances |

| SDS | Serve Don't Sell |

| SEO | Search Engine Optimization |

| SWOT | Strengths Weaknesses Opportunities Threats |

| USB | Universal Serial Bus |

| WBS | Work Breakdown Structure |

1. Introduction

EPS is a one-semester program offered by different universities throughout Europe, including ISEP. The main idea of the program is to provide students with the experience of working together in an interdisciplinary and international team of three to six students and hopes to foster the kind of team-working skills sought after by employers. The goal is to design and develop a new product by combining each other’s knowledge and skills. In this first chapter of the report, the members of our team are presented, and the topic of the project is elaborated.

1.1 Presentation

This team, which is part of the European Project Semester at Instituto Superior de Engenharia do Porto during the spring semester of 2021, consists of five students from different countries and fields of study. These students combined their knowledge and skills to work together towards the same goal, which is stimulating sustainable food production by designing a smart vermiponics system for city buildings.

Our scientific backgrounds are shown below in Table 1.

| Name | Country | Field of study |

|---|---|---|

| Ana Mendes | Portugal | Biomedical Engineering |

| Elena Victoria Tatuc | Romania | Industrial Design |

| Fien Joos | Belgium | Product Development |

| Jakub Wyka | Poland | Mechanical Engineering and Applied Computer Science |

| Kris Petrevski | Macedonia | Information and Communication Sciences for Business and Management |

Team 2 is presented in Figure 1, during an online meeting.

1.2 Motivation

The team members of team 2 have chosen to participate in the EPS program because of multiple reasons. First of all, we are all keen to gain new experiences and to broaden our horizons by stepping out of our comfort zone and take on this new challenge. Secondly, we want to explore new academic fields and new cultures, and working together in an international and multidisciplinary team is a great opportunity to do this and to learn from each other. Next, the scientific, as well as social aspects of the project appeal to us. Finally, we aim to improve our English as well as learn to look at the design process from different points of view.

We believe that participating in the EPS program will be enriching in many ways. We want to develop a project that inspires and connects the members of our team. The vermiponics system is an interesting topic, as it can contribute to a more sustainable environment, which is an urgent need in today’s society.

1.3 Problem

As the world’s population grows, the demands for increased food production expand, and as the stresses on resources such as land, water and nutrients become ever greater, there is an urgent need to find alternative, sustainable and reliable methods to provide this food. The current strategies for supplying more produce are neither ecologically sound nor address the issues of the circular economy of reducing waste [1].

Food production relies on the availability of resources, such as land, freshwater, fossil energy, and nutrients, and current consumption or degradation of these resources exceeds their global regeneration rate. The concept of planetary boundaries aims to define the environmental limits within which humanity can safely operate concerning scarce resources.

As reflected in the UN’s Sustainable Development Goal 2, one of the greatest challenges facing the world is how to ensure that a growing global population, projected to rise to around 10 billion by 2050, will be able to meet its nutritional needs. To feed an additional two billion people by 2050, food production will need to increase by 50 % globally. Whilst more food will need to be produced, there is a shrinking rural labour force because of increasing urbanization. At the same time, food production will inevitably face other challenges, such as climate change, pollution, loss of biodiversity, loss of pollinators, and degradation of arable lands. These conditions require the adoption of rapid technological advances, more efficient and sustainable production methods, and more efficient and sustainable food supply chains.

In short, the global population is rapidly growing, urbanizing, and becoming wealthier. Consequently, dietary patterns are also changing, thus creating greater demands for greenhouse gas (GHG) intensive foods, such as meat and dairy products, with correspondingly greater land and resource requirements. But whilst global consumption is growing, the world’s available resources, i.e. land, water, and minerals, remain finite. Thus, a major global challenge is to shift the growth-based economic model towards a balanced eco-economic paradigm that replaces infinite growth with sustainable development.

In this context, aquaponics has been identified as a farming approach that, through nutrient and waste recycling, can aid in addressing both planetary boundaries and sustainable development goals, particularly for arid regions or areas with non-arable soils. Aquaponics is also proposed as a solution for using marginal lands in urban areas for food production closer to markets. Whilst aquaponics may be considered in the mid-stage of development, there are several allied, novel methods of food production that are aligning alongside aquaponics, and which can be merged with aquaponics to deliver food efficiently and productively. These technologies include algaeponics, aeroponics, aeroaquaponics, maraponics, haloponics, biofloc technology, and vermiponics.

Additionally, there is another aspect to be considered regarding food - food waste. This is a global issue, and only in the European Union (EU), around 88 million tonnes of food are wasted annually, consequently generating costs of 143 billion euros. Food waste is an ethical and economic issue, but it also depletes the environment of limited natural resources. It is estimated that food waste generates eight per cent of Global Greenhouse Gas Emissions. The food wasted should be distributed to the 33 million people in the EU suffering from hunger and malnutrition [2]. Most of the food waste ends up in landfills, making up more than 50 per cent of global landfill waste [3]. This value could be reduced through better use of the organic food waste generated, as it can be composted to form organic fertilisers.

In our project, the focus will be on vermiponics, which uses worm casts of mainly red wriggler worms also known as tiger worms (Eisenia fetida or E. foetida) to provide nutrients in a hydroponic system. Allied to the vermicomposting, we will include a 'keyhole garden' design in our product. It should be noted that vermiponics is in its infancy and mainly practised by hobbyists and in research laboratories. Therefore, it is interesting to explore the possibilities of vermiponics.

1.4 Objectives

The main objective of this project is to develop a modular vermiponics system for residents of a city building. This objective involves designing the product and building and testing a prototype. In the designing phase, our main concerns will be related to the modularity of the system and the smartification of the vermiponics. Sustainable production techniques are already considered during the design phase. Concerning the building phase, a list of materials will be needed and close attention will be paid to assembling the components to secure the relationship between every layer of the vermiponics (the water, the worms, and the plants). Finally, testing the product is essential. Our objective of this phase is to have a working prototype and see actual results.

1.5 Requirements

The requirements of the project include:

- Mandatory adoption of the International System of Units;

- Using open-source software and technologies;

- A maximum budget of 100 €.

Functional requirements:

- Modularity (multiple configurations possible/ multiple sizes,…);

- Low energy consumption (even without any source of energy the system must be able to operate);

- Easy installation and maintenance (design for assembly and disassembly);

- Recyclable components.

Standard requirements:

Comply with the following EU Directives:

- Machine Directive (2006/42/CE 2006-05-17);

- Electromagnetic Compatibility Directive (2004/108/EC 2004 12 15);

- Low Voltage Directive (2014/35/EU 2016-04-20);

- Radio Equipment Directive (2014/53/EU 2014-04-16);

- Restriction of Hazardous Substances (ROHS) in Electrical and Electronic Equipment Directive (2002/95/EC 2003-01-27).

1.6 Envisaged Tests

A set of functional and performance tests are required to verify the operation of the system. These tests are described in table 2.

| Condition | Expected result |

|---|---|

| Temperature and humidity sensor to ensure an optimal environment for the eco-system. | Microcontroller processes the information from both sensors and notifies the user when any adjustments need to be made. |

| Time-of-flight sensors to track the movements of the worms. | Microcontroller processes the information from the sensor and provides information about the position of the worms. |

| IoT platform communication. | The online platform receives values from the microcontroller. |

| Mobile application displaying information. | The app displays the information according to the data sent by the microcontroller. |

1.7 Report Structure

The following table contains the main eight chapters of the report, with a small description of each of them.

| Title | Description | |

|---|---|---|

| 1 | Introduction | Presentation of the team members, of the project purpose,objectives and requirements. |

| 2 | State of the art | Identification of previous knowledge about smart products. |

| 3 | Project management | Overview of the progress in the Agile management and SCRUM. |

| 4 | Marketing plan | Identify the main target group and strategies to introduce our product in the market. |

| 5 | Eco-efficiency Measures for Sustainability | Measures to implement to make the product as sustainable as possible. |

| 6 | Ethical and Deontological Concerns | Analysis of the ethical challenges related to vermiponics. |

| 7 | Project Development | Next steps to be done in order to build the prototype: concept, architecture, components, materials, prototype. |

| 8 | Conclusions | Summary of our project so far and future work. |

2. State of the Art

2.1 Introduction

The general theme ‘smartification of everyday objects’ was the starting point for this project. Before the actual topic of our project was chosen, a study was made about the history and current market of smart products. By gaining insights into this market segment, a better decision could be made on where to innovate and for which object added value could be created through smartification.

The Fourth Industrial Revolution (Industry 4.0) is the automation of normal manufacturing and industrial practices, using smart technology. This Industry gained an increasing amount of attention over the years, and there has been a significant demand for more complex and technological developments [4].

Hoffman and Novak [5] define smart products as products that “interact and communicate with themselves and each other – and with humans – on an ongoing basis by sending and receiving data through the Internet that is stored and organized in a database.” In summary, smart products have:

- Sensors that collect data about the environment, and answer to a physical or chemical stimulus. They can monitor and react to human or/and environmental behaviour. The most common sensors measure temperature, humidity, movement, light, and sound;

- Actuators that are controlled by a Control-Unit (C-U) and activate an action based on the data collected by the sensors. They usually respond by converting the source's energy into mechanical motion and can be categorized depending on the type of motion they present and

- Network connectivity is the process of connecting different parts of a network. This can be achieved via Wi-Fi, Bluetooth, Radio-Frequency Identification (RFID), Local Area Network (LAN), and others.

The three main features of smart products are intelligence, ubiquity, and autonomy. The smart products market is heterogeneous and has many segments (health, smart home, mobility, lifestyle, etc.) and several economic actors (multinationals such as Google and Apple or new start-ups offering innovative products) [6].

2.1.1 Markets and Contexts

A smart product can be categorized into one or more contexts. The main contexts/categories of these products are:

- Smart cities: dealing with congestion, energy waste, improving quality of life.

- Smart home: control appliances, lights, thermostats, and other devices with network connectivity.

- Health: smart medical devices, monitor and transmit data in real-time, connecting doctors with patients.

- Mobility: a multimodal capability that bundles many transport options.

- Lifestyle: these include smart textiles, gadgets, etc.

2.1.2 Consumers' Resistance

The continuous growth of the Internet of Things (IoT) carries challenges and ethical issues, such as lack of human control, doubts about the utility and added value of the product (perceived uselessness), perceived price, the difficulty of usage, privacy, and security concerns, and perceived novelty. The consumers' resistance manifests itself in three forms - rejection, postponement, or opposition -, and the understanding of these manifestations is important for the success of smart products, reducing the risk of failure [7].

2.2 Research Projects

Tobias Mittag et al. [8] studied the recurring smart services and their implementations for manufacturing companies. The selection of ten case studies allowed them to find out the main features of smart products/services and their implementation. To identify the recurring elements, they did a comparative analysis, selecting the recurring functions of the case studies: Product Monitoring, Analytics, Alerting, Communication, Provide Information. Furthermore, this research enhances the importance of creating an overall solution that meets the requirements of the market as customers expect/demand certain services (Market Pull).

Soumitra Chowdhury et al. [9] did a systematic literature review to answer the question “What are the value-creating features of smart product-service systems in industrial firms?”. A Product Service System (PSS) is an integrated product and service that delivers value for the customers and product manufacturers. Smart PSS refers to the incorporation of smart digital technologies in the design and delivery of PSS.

In 2019, Pai Zheng et al. [10] conducted a study on Smart PSS, its key aspects, challenges, and future perspectives, of which they concluded that their findings could be summarized into three different aspects - Technical aspect, Business aspect, and Social and Environmental aspect.

Muztoba Khan and Thorsten Wuest [11] focused on the importance of upgradable PSS, but this logic can be applied to smart products as well. The shorter innovation and product development cycles make consumers dispose of conventional products before the end of their useful lives, that even if the product was considered sustainable, this life-shortening practice, takes away that aspect. Making a product/system upgradable is the right path to approach this problem because as new technologies for product development arrive, one could still take advantage of those, but with the original product/service they bought.

The following table compiles the most important aspects and features of smart products/services according to the different studies mentioned above.

| Project | Theme | Main Features | Business | Design | Manufacturing | Usage |

|---|---|---|---|---|---|---|

| Building blocks for planning and implementation of smart services based on existing products [12] | Smart products/services and their implementation | Product monitoring Analytics Alerting Communication Provide information | 'Use-oriented' business model | Involvement of users in the process | Building blocks Use available data about the system to keep improving it | Monitoring Optimization Service support |

| Smart Product-Service Systems in Industrial Firms [13] | Smart PSS features for added value | Digital resource integration with customers Connect capability Analytic capability | Use generated data to improve customer relationship and PSS redesign | Boundary spanning Dynamic capabilities | Manufacturers have to find ways to exploit digitalization to meet current needs of the digital era | Remote monitoring to reduce machinery breakdowns |

| A survey of smart product-service systems [14] | Key aspects of PSS | Digitalization capabilities (connect, analytic, intelligence) Co-creation | Business model Digital platform Value co-creation Circular economy | Adaptable design Service innovation | Planning Process control | Remote monitoring Reconfiguration Reuse Remanufacturing Recycling at 'end-of-life' stage |

| Towards a framework to design upgradable product service systems [15] | Importance of upgradable PSS | Customization Modularization | Upgradable systems provide a better and continuous relationship with customers | Flexible design to allow rearrangements during the use phase under the customer's requirements, while maintaining minimal structural change | Integrated development of product and service | Collect data about the usage behaviour and taking customer feedback into account |

From this analysis it is possible to say that monitoring is a common and important usage feature, mentioned in each project, to improve the relationship with the customers. Other key aspects to retain are that this relationship with customers should be open and truthful, as the company should provide information about the design and manufacturing stages, as well as service support during the usage stage. Furthermore, the products should be reusable, and/or recyclable products that add value, and the modularization and customization help to create upgradable services/products for greater longevity.

2.3 Commercial Projects

The commercial projects/products are vital in the comparative process of the first research steps, to oversee what is already available on the market, to analyse the qualities and downsides of the products, and to conclude on which features the team's product should compile, and some issues that could be solved with said product.

The next table contains a smart object/product for each context/market mentioned previously, with its description, main features, market, price, and an evaluation of sustainability (environmental, economic, and social) and ethics.

| Product | Context | Description | Main Features | Sustainability | Ethics | Market | Price (€) |

|---|---|---|---|---|---|---|---|

| Bigbelly | Smart cities | Smart waste and recycling system | Solar-powered Sensor-equipped Real-time communication | Environmentally sustainable | Very respectful of ethical issues | Municipalities and cities governors | Not specified |

| Wi-Fi Plug | Smart home | Intelligent plug | Wi-Fi connection Energy-efficient Measurement of electricity consumption Timer to turn on/off | Environmentally and economically sustainable | No issues reported | Everyone who wishes to keep track of their energy consumption and people who forget | 9.99 - 14.00 |

| 8sense by Beurer | Health | Device that vibrates when back posture is not correct or when the person is in the same position for too long | Real-time feedback 14-day memory “8sense” app Lithium-ion battery | Not very sustainable (materials, production) | Ally to preventive health, avoiding back problems | For everyone who desires to correct their posture/maintain it correct | 100.00 |

| MaaS Made Easy | Mobility | Software for easy access to smart mobility (for transport operators, municipalities, and corporations) | Flexibility Integration Cost-effective Route planner Real-time transit data | Sustainable for the environment, the economy, and the community | Privacy data issues can be found due to vulnerabilities of the system | Everyone can benefit from smart mobility strategies | Not specified |

| Smart Watch | Lifestyle | Sports watch | 12 sports modes GPS Heart rate monitor Acceleration, Geomagnetic, Air pressure, Ambient light sensors Bluetooth 5.0 App 14-day battery life | Unsustainable production, but sustainable for the community to monitor vital signs, exercise, etc. | Can be an ally for preventive health Vulnerabilities of the system can be found (potential threat to users) Misused data will also cause bad influence and the companies are not transparent on the usage of personal data | Suitable for everyone | 25.00 - 450.00 |

2.4 Sustainable Food Production Systems

The demands for increased food production caused by the world’s population growth mentioned in section 1.3 (previous chapter) directed the focus of the project to the urban areas, where 55 % of the world’s population lives currently, and is expected to increase to 68 % by 2050 [16]. After evaluating the existing market of smart products, the theme of the project is sustainable food production systems.

2.4.1 Aquaponics

Aquaponics is a food production system. It’s an energy and cost-efficient way to grow plants and vegetables. Aquaponics is based on a system that uses a symbiotic relationship between plants and fish. The main process that occurs in this system is that bacteria convert fish waste into plant food. The plant feeds on this and purifies the water. Fish waste can turn into plant food through the process of the ‘nitrogen cycle’: fish waste contains ammonia (this can not be absorbed by the fish, as it is toxic) so bacteria convert the ammonia to nitrate. Two types of bacteria are necessary to do this - the first bacteria (Nitrosomonas) converts ammonia to nitrite, and the second bacteria (Nitrobacter) converts nitrite to nitrate [17].

Figure 2 illustrates what an aquaponics system generally looks like.

Advantages of aquaponics [19]:

- No artificial fertilizers/ other agricultural fertilizers: obtain high-quality, chemical-free food that is safe for human health;

- Saves 95 % water compared to cultivation methods;

- Production is completely independent of the weather and climate;

- Energy savings of up to 70 % can be achieved compared to traditional horticulture;

- Plants have constant access to nutrients which allows them to grow faster (e.g.: lettuce can grow in 1 month compared to the 'normal' 2 months);

- The aquaponics system does not use large, environmentally damaging agricultural machinery.

2.4.2 Vermiponics

As more research on aquaponics was conducted, it became clear that there are valid arguments as to why aquaponics may be an ecologically minded and economically viable option. However, currently, the vast majority of aquaponic systems are simply not sustainable [20]. It turns out that there are a lot of alternatives, like vermiponics, that represent theoretical and technical progress towards sustainable primary production.

Vermiponics is a novel way to grow plants that uses the nutrients from worm castings (specifically from worm-tea) to grow plants in a soil-less (or hydroponic) environment. Vermiponics is similar to aquaponics (which is also soil-less) but instead of the nutrients being provided by fish waste that is broken down by bacteria, the nutrient solution in vermiponics is made from worm-tea instead. Worms can create an effective organic fertilizer for plants, as they decompose organic matter and food scraps. This process is called vermicomposting. The result of this process is compost tea/worm-tea, which serves as a non-toxic alternative to chemical fertilizer [21].

The following image illustrates what a vermiponics system generally looks like.

Several reasons that justify vermiponics being more sustainable than aquaponics are listed below [23]:

- Vermiponics does not require equipment for heating or cooling because the operating range for vermiponics is 7-32 °C. An aquaponic system with Tilapia, for example, has operating temperatures between 21-32 °C which often creates a need for climate control and/or greenhouse;

- Vermiponics does not require filtration systems. Solids are not a problem for worms and the microbiome, and plant roots remove excess solids when the plants are harvested;

- Vermiponics does not need large stock tanks for fish. Fish tanks take up 10-100x more space than vermiculture systems;

- Fish food is grown with conventional agriculture (land-intensive and water-intensive) so the complete footprint for aquaponics is quite large. Vermiponics has no additional land use, as nutrients come from food waste that would otherwise end up in a landfill;

- Nutrient density of vermiponics solution is approximately three times that of aquaponics;

- Worms are far more robust than fish, as it is easy for fish to die from disease or system malfunction (loss of temperature control, oxygen, circulation, nutrient toxicity). The only way a worm population will die is if the vermiculture system gets below 1.7 °C or above 37.8 °C, which is very unlikely to happen.

2.4.3 Permaculture and Keyhole Gardens

A permaculture is an approach that integrates land, resources, people, and the environment to mimic the natural systems with no waste loops [24]. The following figure sums up the concept of permaculture and other aspects associated with it.

At this point, there are a few solutions that respect the approach of permaculture. One of these is the African keyhole garden, which was designed by CARE in Zimbabwe during the mid-nineties to encourage people to grow their own food. A keyhole garden is a round garden bed with a compost pile in the middle. The garden has a notch in the front, so gardeners can easily add to or turn over the pile. It also has a drainage layer, a soil layer, and a planting area, which combine all the necessities that plants need to grow and thrive [26].

2.4.4 Conclusion

To sum up, the systems involving vermiponics and/or vermicomposting are the most sustainable for food production. Furthermore, it is also clear that imitating natural systems is the most ethical, energy-efficient, and sustainable approach. After plenty of discussion and consideration, the team decided to implement a system that consists of a simple modular 'keyhole garden' structure, with a composting basket in the centre. The team considers this to be an interesting product to smartify, as variables such as temperature, and humidity are important to monitor, and a tracking device could add value to the system.

2.5 Related Solutions

2.5.1 Subpod

Subpod is an in-ground compost system, as seen in Figure 6, that turns food scraps, paper, coconut peat into rich compost. Over time, the worms living in it provide the nutrients from the compost to the garden soil, helping the plants thrive [27].

2.5.2 Biovessel

The BioLad and Engineering/Design studio 'BIONICRAFT' is dedicated to biological research, conservation, and innovation. Through biological observation and experiment, they designed the 'BIOVESSEL'. The BIOVESSEL is “an ecosystem powered by food waste”, as their slogan states, that aims to deliver nature to urban homes composting food waste for a sustainable lifestyle [29].

2.5.3 Urbalive

Urbalive provides different options for indoors and outdoors: from simple vermicompostors (“Worm Farm”) to farming systems (“Indoor Planter” and “Outdoor Planter”) [31].

2.5.4 Comparison

| Product | Price (€) | Pros | Cons |

|---|---|---|---|

| Subpod | ~300 | Different sizes Provides everything needed for composting | Price Availability for outside the United Kingdom is conditioned Mainly recommended for outdoors |

| Biovessel | ~200 | Small, portable Great for the inside Appealing design (can be seen as decoration) | Price Little space for plants (fits only one) No information available after 2018 |

| Urbalive | 100-160 | Portable Modular They sell individual trays Cheaper Solutions for both indoors and outdoors Self-watering | The worm tea production and plant production have to be done in separate places/products, and this way it becomes more expensive (~260 €) |

As seen in Table 6, indoor food production is conditioned in the three products analysed. Subpod is perfect for outside (gardens, backyards, etc.), while Biovessel is idealized for the inside, but only for vermicomposting, as it has no space for food production, given the size of the product. Urbalive would be more interesting if everything was combined in one product (plant production and vermicomposting). Therefore, the combination of greater space for plant production with an appealing design is something that has not yet been achieved in the vermicomposting market.

2.6 Summary

Nowadays, endless smart products can be found on the market, with different applications. These objects are divided into five main contexts/markets: smart cities, smart homes, health, mobility, and lifestyle. There are common features for these markets, including remote monitoring, digitalization, and adaptability. Furthermore, people look more and more for products on which they can have a say, on which their opinion matters, and having customers' loyalty and trust is important for companies.

Based on this study of the state of the art, the team decided to adopt the following strategies: manufacture a modular/reconfigurable product with connectivity; develop a product that adds value and that answers to the existing problem of sustainable food production in today's society; choose the most sustainable production strategies and materials possible; be communicative with customers, and open about the manufacturing process and materials used. Therefore, the team will develop a smart modular 'keyhole garden' structure, to fulfil the need for sustainable food production techniques as the world's population grows.

The following chapter is an overview of project management throughout the semester.

3. Project Management

The team followed the agile project management methodology named Scrum, due to its short, iterative cycles (sprints) and flexibility. This is a simple framework to implement and it solves problems such as development cycles, inflexible project plans, and shifting production schedules [33].

3.1 Scope

The scope of the project is important because it gives the team guidelines for making decisions during the project development. It involves determining and documenting what must be done to deliver a product according to its scope, which compiles the functions and features that characterize the product/service [34].

A properly defined scope allows estimating costs and the time required to finish the project. It helps to determine tasks and distribute all resources. After defining the main goal of the project the team improved the planning by a simple hierarchical structure consisting of all tasks and products that are needed to successfully finish the project. By the means of Work Breakdown Structure (WBS), the team divided the scope into six sections: Initial, Design, Interim, Executive, Test, and Final. Multiple tasks belong to each stage, as seen in Figure 9.

3.2 Time

One of the main criteria to succeed in any project is correct time management. For correctly managing their time, the team creates deadlines, sprint plans, and divides tasks while also estimating the time required for each assignment. This ensures continuous workflow and productive sprints. In case some tasks require a longer time than estimated or if they are not performed in time, the whole time management may be affected. This is why it is important to organize the time from the beginning and respect the deadlines assigned to each task.

Using a global sprint plan the team defined the optimal sprint duration and planned the sprints until project end. After that, the project backlog was created including all relevant tasks and deliverables. Based on these the Gantt Chart was developed (Figure 10), using the software GanttProject.

3.2 Cost

In this section, the planned and effective costs of the project are documented. This is important to keep track of the costs and to not go over the budget.

Materials

The cost of the materials for the product can be consulted in the Deliverables section. There, one can find the list of materials for the prototype and also the list of materials for the actual product. In chapter 7, Project Development, we go into more detail regarding the materials and components.

Human Resources

Human resources also play a key role and it is important to include these in the cost. For people to be motivated, rewards are presented, which consist of monthly payments (salary). If the team decides to establish a firm in Porto, where an engineer earns on average 1459 € per month [35] and considering that as a start-up the company would not have profit, the wage of the team members would be lower than the average, as seen in Table 7.

| Employee | Monthly wage (€) | SS - 23.75 % (€) | FCT - 5 % (€) | Insurance (€) | Total (€) |

|---|---|---|---|---|---|

| Ana | 1000 | 1237.5 | 50 | 30 | 1317.5 |

| Elena | 1000 | 1237.5 | 50 | 30 | 1317.5 |

| Fien | 1000 | 1237.5 | 50 | 30 | 1317.5 |

| Jakub | 1000 | 1237.5 | 50 | 30 | 1317.5 |

| Kris | 1000 | 1237.5 | 50 | 30 | 1317.5 |

| Total | 5000 | 6187.5 | 250 | 150 | 6587.5 |

3.3 Quality

Two principles are ensuring good quality: “Right First Time” - the final product should be free from mistakes and “Fit for Purpose”.

Quality assurance is a complex process. It includes management of the quality of products and components, raw materials, assemblies, as well as services related to production, management, and inspection processes.

Wormify specializes in the production of vermiponics system to be as efficient as possible. This is why quality plays a major role in the whole process. These systems are to stay within the standards to provide proper use. Our company meets the following quality aspects:

- Material & Component Quality;

- Product Quality;

- Employee & Team Work Quality;

- Time Quality.

Regarding materials and components, our team wants to use the best materials, taking into consideration sustainability and low impact on the environment. In this case choice of natural materials, minimizing the number of non-renewables is obvious. All the chosen materials are recyclable, mostly aluminium and bamboo. Not only they provide sustainability but also an aesthetic impression.

In terms of product quality, if the requirements are met, it can be said that it satisfies users. As vermiponics provide needs and, in addition, introduce the term of innovation and bring people together, it becomes a desirable product on the market.

To achieve good employee&team work quality, the sense of ownership must be fulfilled. One always takes better care of something that they possess as compared to something that they do not. They feel responsible for the outcome of the product. Reaching a good reputation on the market by the product or service will make the employees feel proud. Through teamwork and participation in product development, a sense of ownership is accomplished.

Time is the key factor in carrying out a project. Having the goal well set and the budget assured, time is the guideline for the project. Thus, if time management is achieved and respected, the project will be carried out in good parameters. Using the Scrum method to organize the tasks for the project we stuck to deadlines.

It seems that quality is a major category that consumers use to evaluate a product or service. Meeting users expectations is crucial for people involved in a business and is driven by the market conditions such as competition.

3.4 People

Human resources are the key factor for a project. Team members contribute to multiple task development. To help organize the work different tasks were allocated to team members. What is more the team knows who is responsible for a certain task. It is visible in the following table.

| Task | Responsible |

|---|---|

| Teambuilding report | Ana |

| Topic choice | Jakub |

| State of art and project backlog | Jakub |

| Blackbox | Ana |

| System schematic and structural drawings + cardboard model | Fien |

| List of materials | Kris |

| Interim report and presentation | Elena |

| List of materials (revised): local providers & price, including VAT & transportation | Fien & Jakub |

| Refined design of the product | Elena & Ana |

| Revised interim report | Kris |

| Start Design | Jakub |

| Finalize design | Elena & Fien |

| Finalize design: high fidelity prototype | Kris & Ana |

| Upload result of functional tests | Ana |

| Upload final report + presentation + video + paper + poster | Jakub |

| Final presentation | Fien |

Not only the team members are involved in the project development. These people together with the team members are called stakeholders. A stakeholder is a person such as an employee, customer, or citizen who is involved with an organization, society, etc., and therefore has responsibilities towards it and an interest in its success [36].

| Stakeholder | Role |

|---|---|

| Team members | Students |

| Benedita Malheiro | EPS coordinator |

| Benedita Malheiro, Cristina Ribeiro, Jorge Justo, Manuel Silva, Paulo Ferreira, Pedro Barbosa Guedes | Supervisors |

| Ana Barata, António Arrais de Castro, Cláudia Facca, Luís Castanheira, Luís Lopes, Paulo Ferreira, Sandra Luna | Teachers |

3.5 Communications

Good communication within the team is essential to obtain a successful project outcome. Because of the pandemic situation and to ensure the good flow of information the following communication methods were introduced:

- Meetings - mainly on Zoom and Microsoft Teams.

- Email - used to communicate with teachers and supervisors.

- Chat - WhatsApp and Messenger groups to access quick, everyday communication between team members.

- Other apps - Microsoft Planner, Microsoft OneNote, Google Drive, Canva.

| What? | Why? | Who? | When? | How? |

|---|---|---|---|---|

| Deliverables | Develop the project | Team members | Before the deadlines | Uploading to Wiki and presenting to the supervisors/teachers |

| Weekly team meeting | To gain feedback | Team members, supervisors | Every Thursday | Microsoft Teams |

| Everyday stand-up | Discuss the work being done on the previous day, set new tasks | Team members | Everyday | Microsoft Teams |

| Sprint planning | Divided into team members, set deadlines and add tasks to the project Backlog | Team members | Every Monday | Microsoft Planner |

| Sprint review | To check the progress | Team members | Every Friday | Microsoft Planner |

| Brainstorming | To find new ideas | Team members | Before taking action | Microsoft Teams, WhatsApp, Messenger, Google Drive |

| Agenda | To pick the topics for meetings with supervisors | Team members | Every Wednesday | Wiki |

| Interim Presentation | To present the current state of the project and obtain feedback from the supervisors | Team members, supervisors | April 22, 2021 | Microsoft Teams |

3.6 Risk

Risk is the possibility of loss or injury. Risk analysis and management is an important project management practice to prevent surprises during project development. The lack of a structured risk management framework leads to:

- Incomplete impact evaluation: no knowledge of the impact on the project goals (scope, time, cost, and quality)

- Lack of transparency and communication gap between team members and outside the team.

Therefore, the implementation of such a framework will provide a conscious and focused risk identification/management, the envisioned project progress with minimal surprises, early and effective communication of project issues, and an effective team-building tool.

The following two tables are related to product and project risks. The risks are evaluated through the following criteria:

- Impact, which can be low, medium, or high;

- Probability, on a scale of 1 (no-very low probability) to 4 (very high probability).

3.6.1 Product Level

| Risk | Cause | Effect | Evaluation | Mitigation |

|---|---|---|---|---|

| Functionality | Problems with suppliers, lack of necessary skills | Incomplete product | Impact: high Probability: 2 | Prototype development and testing, focus on evolving required skills |

| Performance | Wrong mechanisms | Lower sales, unsatisfied customers, bad reviews | Impact: high Probability: 2 | Intensive research and testing |

| Design | Improper design | Lower sales because of the product aesthetics | Impact: high Probability: 3 | Present different designs to different individuals and choose the most liked and efficient one |

3.6.2 Project Level

| Risk | Cause | Effect | Evaluation | Mitigation |

|---|---|---|---|---|

| Team conflicts | Lack of communication | Delays | Impact: high Probability: 2 | Early communication, open discussions, compromising |

| Lack of skills | Lack of expertise in a certain field | Delayed work, inappropriate development of tasks | Impact: high Probability: 2 | Research, turn to supervisors for guidance |

| Time management | Wrong estimations | Delayed work, inconsistent & unfinished sprints | Impact: medium Probability: 3 | Weekly sprint reviews and evaluation |

3.7 Procurement

Procurement is the process of acquiring and buying products, goods and services from external suppliers. This process is essential as the team has to find local suppliers who can provide Wormify with the best possible price and high quality for the needed goods. All parts available in standard formats are bought to save time. In other cases, i.e. the connectors, they are manufactured with the most suitable technique. This gives us money-saving as no margin by the seller is involved and independence of external suppliers.

As sustainability is an important factor, the team must search for suppliers that attach importance to that and try to minimize the number of supplier companies, which is especially important to save costs and transportation pollution.

3.8 Stakeholders Management

The stakeholders' analysis is a structural approach allowing the understanding of a system, by specifying the interests, needs and concerns of the organisms concerned. This tool is especially useful when:

- Resources are limited

- Different stakeholders have opposite interests

- Needs of different parts have to be balanced

- Evaluating another scenario

The method of the stakeholders’ management will be defined in 4 steps:

1. Identify the stakeholders

Firstly list and rate the stakeholders. Then organize it based on 3 levels of involvement: direct (affected directly), secondary (addicted but not directly) and key (actively involved in the project).

2. Value the interest of stakeholders and the potential impact on the project

3. Evaluate the influence and importance of the stakeholders

Rate each stakeholder taking into consideration the following points:

- Power and status (political, social, economic)

- Level of organization

- Control over strategic resources

- Importance in the project success

4. Draft of the strategy of participation of stakeholders

- Weak interest stakeholders with weak role will probably be not very involved in the project and they do not require a particular strategy

- Weak interest stakeholders, but with a powerful role need special efforts to ensure that their expectations are considered and their participation is constructive

- Strong interest stakeholders with a weak role are not who we aim, although they can be opposition, thus, we must keep them informed and acknowledge their viewpoints to avoid disagreement or conflicts

- Strong interest stakeholders and a powerful role should be associated with all project long to ensure their support

The table below shows the comparison of the impact of stakeholders on vermiponics.

| Stakeholder Impact | Strong Influence | Weak Influence |

|---|---|---|

| Strong Power | Team members, EPS Coordinators | Government |

| Weak Power | Vermiponics users, Suppliers | Mass customer, other EPS participants |

3.9 Sprint Outcomes

Scrum is an Agile project management methodology involving a small team led by a Scrum Master, whose main job is to remove all obstacles to getting work done. Work is done in short cycles called sprints, and the team meets daily to discuss current tasks and any roadblocks that need clearing [37]. This framework uses the following:

- Daily stand-up. It is an everyday meeting in which team members discuss the work being done on the previous day, plan the current day, and review the obstacles that have occurred. It is worth mentioning that those meetings should be carried out in a standing position.

- Sprint planning. Every Monday, at the begging of each sprint, the team plans what will be done this week. Then the tasks are allocated to the different team members and their duration is estimated.

- Sprint review. Every Friday, at the end of each sprint, the team reviews the last sprint plan. The tasks are divided into completed and not completed.

- Sprint retrospective. Apart from sprint review, the sprint retrospective takes place every Friday. It is reflected what was positive and what was negative during the last sprint. Based on these three categories are created: start doing, keep doing, and stop doing.

Based on the academic calendar delivered by ISEP, the number and duration of sprints were adjusted. It is shown in Table 14.

| Sprint | Start | Finish |

|---|---|---|

| 1 | 01/03/2021 | 07/03/2021 |

| 2 | 08/03/2021 | 14/03/2021 |

| 3 | 15/03/2021 | 21/04/2021 |

| 4 | 22/03/2021 | 28/03/2021 |

| 5 | 29/03/2021 | 04/04/2021 |

| 6 | 05/04/2021 | 11/04/2021 |

| 7 | 12/04/2021 | 18/04/2021 |

| 8 | 19/04/2021 | 25/04/2021 |

| 9 | 26/04/2021 | 02/05/2021 |

| 10 | 03/05/2021 | 16/05/2021 |

| 11 | 17/05/2021 | 23/05/2021 |

| 12 | 24/05/2021 | 30/05/2021 |

| 13 | 31/05/2021 | 06/06/2021 |

| 14 | 07/06/2021 | 13/06/2021 |

| 15 | 14/06/2021 | 20/06/2021 |

| 16 | 21/06/2021 | 25/06/2021 |

Project Backlog is built including all relevant tasks and deliverables. Project Backlog Items (PBI’s) are prioritized, keeping higher priority items at the top, and lower priority items at the bottom. Each task has a status: To-do, Doing, or Done. It means that the Project Backlog is continuously updated. When the task is done it goes to the bottom of the table.

| PBI | Title | Status |

|---|---|---|

| TR | Teambuilding report | Done |

| TC | Topic choice | Done |

| SA | State of art and project backlog | Done |

| BB | Blackbox | To do |

| SSS | System schematic and structural drawings + cardboard model | Done |

| LM | List of materials | Done |

| IR | Interim report and presentation | Done |

| LLR | List of materials (revised): local providers & price, including VAT & transportation | Done |

| RDP | Refined design of the product | Done |

| RIR | Revised interim report | Done |

| SD | Start Design | Done |

| FD | Finalize design | Done |

| FD | Finalize design: high fidelity prototype | Done |

| FT | Upload result of functional tests | Done |

| FR | Upload final report + presentation + video + paper + poster | Done |

| FP | Final presentation | Done |

Below the completed sprints are presented. As mentioned before they are weekly, based on the Global Sprint Plan and Project Backlog.

| Sprint Plans | ||||

|---|---|---|---|---|

| Sprint 4 (22/03 - 28/03) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Weekly classes | 60 | 60 | Ana, Elena, Fien, Jakub, Kris | Done |

| Finish and upload Blackbox to Wiki | 1 | 1.5 | Kris | Done |

| State of the art | 2 | 3 | Fien | Done |

| Make final product choice | 6 | 4 | Ana, Elena, Fien, Jakub, Kris | Done |

| Sprint 5 (29/03 - 04/04) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Define target group | 3 | - | Elena | Doing |

| Weekly classes | 58 | 58 | Ana, Elena, Fien, Jakub, Kris | Done |

| Research about symbiotic relations | 3 | 2.5 | Jakub | Done |

| Sketches | 3 | 3 | Fien | Done |

| Electronics schematics | 2 | 2 | Ana | Done |

| Finish and upload state of the art to Wiki | 2 | 2 | Kris | Done |

| Sprint 6 (05/04 - 11/04) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Detailed system schematics & structural drawing | 4 | - | Fien | Doing |

| Refine Blackbox | 2 | - | Kris | Doing |

| Weekly classes | 40 | 40 | Ana, Elena, Fien, Jakub, Kris | Done |

| MACOM presentation | 3 | 3 | Ana | Done |

| Energy & Sustainable Development presentation | 2 | 2.5 | Jakub | Done |

| ETHDO: choice for the case study | 1 | 1 | Elena | Done |

| Sprint 7 (12/04 - 18/04) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Upload Interim Report | 50 | - | Ana, Elena, Fien, Jakub, Kris | Done |

| Cardboard scale model | 6 | - | Fien, Ana | Doing |

| Weekly classes | 55 | 55 | Ana, Elena, Fien, Jakub, Kris | Done |

| Sprint 8 (19/04 - 25/04) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Finish cardboard scale model | 5 | - | Fien | Done |

| Prepare interim presentation | 45 | - | Ana, Elena, Fien, Jakub, Kris | Done |

| Detailed System Schematics & Structural Drawing | 30 | - | Fien, Ana | Doing |

| Weekly classes | 20 | 30 | Ana, Elena, Fien, Jakub, Kris | Done |

| Sprint 9 (26/04 - 02/05) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| List of materials | 20 | 15 | Ana, Elena | Doing |

| Project development | 50 | 45 | Ana, Elena, Fien, Jakub, Kris | Doing |

| Refine design | 5 | - | Fien | Doing |

| Weekly classes | 50 | 45 | Ana, Elena, Fien, Jakub, Kris | Done |

| Sprint 10 (03/05 - 16/05) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Leaflet (first draft) | 2 | 2 | Elena | Done |

| Start Research Paper | 1 | 1.5 | Ana | Done |

| Power budget | 5 | - | Ana | Doing |

| Sustainability presentation | 15 | 15 | Ana, Elena, Fien, Jakub, Kris | Done |

| 3D video | 5 | - | Elena | Doing |

| Apply teachers' feedback to report | 6 | 5 | Ana, Kris | Done |

| Refined interim report | 20 | 20 | Ana, Elena, Fien, Jakub, Kris | Done |

| Classes | 75 | 75 | Ana, Elena, Fien, Jakub, Kris | Done |

| Sprint 11 (17/05 - 23/05) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Improve 3D video | 1.5 | 2 | Elena | Done |

| Finalize power budget | 1 | 1 | Ana | Done |

| Start building proof-of-concept | 4 | - | Ana, Fien, Kris | Doing |

| ETHDO presentation (case study) | 2 | 2 | Jakub | Done |

| Classes | 50 | 50 | Ana, Elena, Fien, Jakub, Kris | Done |

| Sprint 12 (24/05 - 30/05) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Start user manual | 6 | 6 | Fien, Jakub | Done |

| App mock-up | 10 | 10 | Ana, Kris | Doing |

| Create presentation on the marketing chapter | 4 | - | Kris | Doing |

| Test technical components | 2 | - | Ana | Done |

| Classes | 45 | 45 | Ana, Elena, Fien, Jakub, Kris | Done |

| Sprint 13 (31/05 - 06/06) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Leaflet (final version) | 1 | - | Elena | Done |

| User manual (first draft) | 4 | - | Fien | Done |

| Poster (first draft) | 2 | - | Elena | Done |

| Ethics chapter (final version) | 2 | - | Ana | Done |

| Marketing chapter presentation | 2 | - | Kris | Done |

| Collect materials for prototype | 2 | - | Ana | Done |

| Improve paper | 3 | 3 | Jakub | Done |

| Start final presentation | 1 | - | Fien | Doing |

| Classes | 30 | 30 | Ana, Elena, Fien, Jakub, Kris | Done |

| Sprint 14 (07/06 - 13/06) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Build supporting structure | 20 | - | Ana, Elena, Fien, Kris | Doing |

| Research on materials for the actual product | 3 | 3 | Jakub | Doing |

| Finish the manual (safety guidelines + FAQ) | 2 | - | Fien | Doing |

| Calculations - bending strength of bamboo | 2 | - | Elena | Doing |

| Improve poster | 2 | - | Elena | Done |

| Packaging | 6 | 5 | Ana, Fien | Done |

| App | 5 | - | Kris | Doing |

| Portuguese presentation | 2.5 | - | Ana, Elena, Fien, Jakub, Kris | Done |

| Classes | 35 | 35 | Ana, Elena, Fien, Jakub, Kris | Done |

| Sprint 15 (14/06 - 20/06) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Implement electric circuit on prototype | 4 | 2.5 | Ana | Done |

| Finish code | 8 | 8 | Kris | Done |

| Finish prototype | 16 | 20 | Ana, Elena, Fien, Kris | Done |

| Finish Project Management chapter | 3 | - | Jakub | Done |

| Final Deliverables | 20 | 25 | Ana, Elena, Fien, Jakub, Kris | Done |

| Classes | 40 | 40 | Ana, Elena, Fien, Jakub, Kris | Done |

| Sprint 16 (21/06 - 30/06) | ||||

| Task | Estimated duration (h) | Real duration (h) | Members involved | Status |

| Final presentation | 30 | - | Ana, Elena, Fien, Jakub, Kris | |

3.10 Sprint Evaluations

Using Microsoft Planner and Microsoft OneNote we planned our sprints. It allowed us to review each sprint. Those tasks that were not completed were delayed for the next week until being finished.

The positive sides as for now are final project choice and good teamwork. Thanks to this we can focus on the goal, which is clearly stated. We would love to develop sustainable vermiponics combining it with a water collecting system with a good design using efficient materials. We are looking forward to creating a 3D model prototype based on sketches. In further steps, it is necessary to take into consideration marketing aspects such as branding of our product, ethical ones as well as established budget. Unfortunately, there are also negative sides. One of them is online meetings which result in poor interpersonal contact and difficulties in decision making.

3.11 Summary

Good project management is a pillar that ensures a project development is done with quality, on time and within the budget. It is a very complex process including tracking deadlines, setting a budget, taking control and ensuring that the project has stakeholders support and what is more it lasts from the very beginning to the end of the project.

In the next chapter, 4. Marketing Plan, our team will be introduced in the Marketing term, which is an important strategy to ensure the growth of our business. Current customer will always be our priority. Thanks to the marketing efforts this base can expand. Nowadays social media is a powerful tool to maintain presence and acquire new customers. In brief, marketing provides our business with a better future.

4. Marketing Plan

4.1 Introduction

Creating a marketing plan is critical for any business. Developing a marketing plan will help us think about the purpose, buyer personas, budget, methods, and deliverables for each campaign. We will be able to keep on track with a campaign, notice what works and what does not, and measure the effectiveness of our brand strategy if we have all this information in one place.

The focus of our strategy will be to ensure that Wormify meets client needs and develops long-term and profitable relationships with those clients. To do this, will develop a flexible strategy able to adapt to changes in customer perceptions and demand.

The business environment is a marketing term used to refer to the circumstances and forces that influence a company's capacity to establish and maintain effective customer connections. In this chapter, the first step in achieving this goal is to identify micro and macro factors.

Second, we will conduct an honest and comprehensive SWOT analysis of our marketing strategy document, looking at our strengths, weaknesses, opportunities, and threats. We will perform market research on existing customers to get a more accurate picture of our reputation in the marketplace.

The third step is to identify the strategic objectives by using the SMART methodology. Specific and measurable objectives define the success of a project or initiative. Fourth, we will visualize Wormify concerning the market and competition. Fifth, we will focus on the 4C’s of the marketing mix to decide how to take the new offer to the market and to test our marketing strategy. The final focus will be on the budget and strategy control to ensure that the marketing objectives are attained.

4.2 Market Analysis

A market analysis is an in-depth examination of a market within a particular sector. We will investigate the dynamics of your market, such as volume and value, potential consumer segments, purchasing habits, competition, and other important factors, with this report.

Knowing the market environment will enable us to foresee our current position and establish the potential position of our product on it.

Looking at the environment, a distinction can be made on three levels: macro, meso, and micro.

Macro – contextual level

The contextual level consists of ‘global forces’, such as economic development, demographics, politics, technological developments, and social developments.

Meso – transactional level

The transactional level consists of ‘market forces’, such as suppliers, supply and demand, distribution, competitors, and strategic alliances.

Micro – organizational level

The organizational level includes factors that handle the firm's internal climate. Think about: vision, mission, strategy, resources, processes, products, and services.

Looking at each level's factor will help the Team understand the situation prevailing on the market. Figure 11 presents components of business environments.

Having the information from the market analysis will help us strengthen our market position, minimize investment risk, meet customer needs and demands while staying ahead of the competition. Therefore, we can prepare a valuable product more accurately.

4.2.1 Problem Statement

Vermicomposting is an eco-biotechnology that employs earthworms in the decomposition of organic matter. Given global pro-environmental politics, it could be regarded as an interesting eco-innovation in biowaste management. As a result, it is perfectly suited to the circular economy concept, turning different types of organic waste (domestic and industrial) into renewable energy sources or “biosoils”. It also acts as an alternative to other waste management approaches that are considered unfriendly to the environment. Several different types of organic waste, such as by-products from various industries, have recently been proposed as substrates in the process. Some beneficial properties of vermicompost make it an interesting product for agriculture, gardening, and remediation of polluted areas. Vermicomposting on a large scale is necessary to effectively and globally solve the waste disposal problem.

4.2.2 Internal Analysis

7S Model of McKinsey for internal analysis

To prepare an analysis on our Team – we have decided to take advantage of the 7S McKinsey model as a framework. The model can be applied to many situations and is a valuable tool to improve the performance of your organization or to determine the best way to implement a proposed strategy. The specific layout of the McKinsey model is shown in Figure 12. 7S McKinsey's model examines the factors internal to the organization that can affect its success. It is therefore a useful way of identifying strengths and weaknesses as part of a SWOT analysis.

Strategy – the aim of the company and how the organization intends to increase its competitive advantage

Teams generate new knowledge in an organization by combining the explicit and tacit knowledge of individual team members. Team leaders who appreciate implicit knowledge will significantly increase the efficiency of individual interactions and group cohesiveness.

Structure - the division of activities; integration and coordination mechanisms

As team members are active in making decisions, they develop a professional and personal interest in the company and its overall performance. This contribution contributes to improved efficiency as participants are actively involved in different aspects of the project and wish to see their efforts succeed overall. This not only helps with project completion but also simulates a real-world work scenario.

Systems - the main and secondary tasks that are part of the day-to-day operations of the company

Monitoring is critical because it allows the team to ensure that you are meeting your objectives. It also demonstrates that you are performing to the highest level you believe is possible. This assists you in determining ways to improve your results. The project managers are often kept up to date on the team's results.

Skills - the human capital of the organization's skill set and capabilities

The team is composed of members who are dependent on each other, work towards interchangeable achievements, and share their expertise in a specific field. Ana Mendes: Biomedical Engineering; Elena Victoria Tatuc: Industrial Design; Fien Joos: Product Development; Jakub Wyka: Mechanical Engineering and Applied Computer Science; Kris Petrevski: Information and Communication Sciences for Business and Management.

Each of us is comfortable with using most project development and research tools towards project completion.

Staff - the team’s core competencies and distinctive capabilities

Identifying and organizing work around each team member's specific strengths and skills ensures enhanced team member performance and commitment, as well as increased efficiency, which contributes to a successful project. It's no wonder, then, that cultivating a strengths-based organizational culture is regarded as critical to the future of work.

Style - key groups' typical behaviour patterns, such as managers and other professionals

Teamwork is organized by using the Scrum method. In Scrum, the development team is self-led, and every member works together to complete each sprint. The members of the development team agree on how to better complete the deliverables.

Shared Values - what engenders trust and link the team together

We collaborate to achieve shared goals by developing relationships based on mutual respect, constructive communication, and trust. We achieve our goals by self-motivation, resourcefulness, and the ability to change as we go. We go above and beyond to add value to the project and our customers. To achieve our goals, we use both our individual and collective abilities.

4.2.3 External Analysis

The environmental determinants research takes into account three aspects of the environment: the macro-environment, and meso-environment. Furthermore, we will use PESTLE to provide a deeper understanding of the industry, alertness to risks, and a method to exploit opportunities. We'll go through each in greater detail.

4.2.3.1 PESTEL Analysis

PESTEL analysis is a strategy for reducing business risks. We can obtain useful advantages by investigating the Political, Economical, Social, Technological, Legal, and Environmental factors. These benefits aid in the concept process, product creation, product launch, content marketing strategies, and other factors that contribute to success. PESTEL analysis will assist the Team in considering a wide range of influential factors that may influence the success or failure of our product.

- Political

The product does not have any political impact, thus this category is not relevant for our project.

- Economic

Vermicompost production is also an ‘economically productive’ process as it ‘reduces wastes’ and consequently saves landfill space. Construction of engineered landfills incurs 20 to 25 million US dollars upfront before the first load of waste is dumped. Over the past five years, the cost of landfill disposal of waste has increased from 29USD to 65USD per ton of waste in Australia. [38]

Earthworms turn a ‘negative' economic and environmental value commodity, ‘waste,' into a ‘highly positive' economic and environmental value product, ‘highly nutritive organic fertilizer' (brown gold), which improves soil fertility and farm productivity to generate ‘safe food' (green gold) in farms. Vermiculture has the potential to preserve the global ‘human sustainability cycle,' which entails processing food in farms from food and farm waste.

- Social

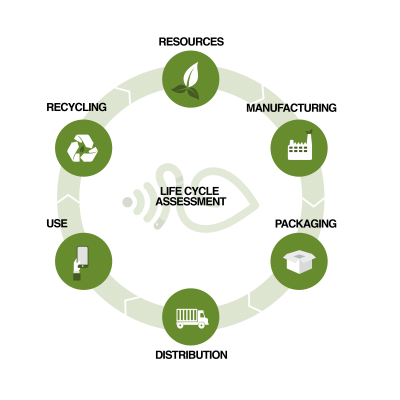

Life Cycle Assessment (LCA) demonstrated that vermicomposting performed satisfactorily in terms of global warming and eutrophication potential while dumping the vermicompost produced could lead to increased eutrophication. However, this is still much lower than the eutrophication caused by untreated manure dumped openly.

- Technological

The product is based on advanced vermiculture technology that transforms organic waste into value-added environmentally friendly goods that can increase soil fertility and productivity on a large scale.

- Legal

Over 4500 unregulated composting/vermicomposting operations are estimated to be present, posing a risk to soils and groundwater. The vast majority of these small-scale operations (approximately 95%) are vermicompost producers on a small scale. There are only 15 managed and legally permitted vermicomposting plants, and the number of plants producing legally authorized vermicompost is currently limited to 15. This number needs to increase for Turkey to become a leading producer of vermicompost by 2023 [39].

- Environmental

Earthworms are natural recyclers. They play an important role in breaking down organic matter and fertilizing the soil simply by feeding and pooping regularly (about 1.5 times their body weight a day). The worm cast that comes from the other end is rich in nutrients and bacteria that are beneficial to plants. Scientists discovered that worm casts contain up to five times the amount of key nutrients found in the surrounding soil.

Competitive Matrix

A competitive matrix is a technique for industry analysis that analyses the attributes of different brands in your market sector to determine their differences, strengths, and weaknesses. This data assists you in identifying your unique competitive edge and prospects for business growth.

We will use a competitive matrix in a form of a chart that lists each competitor along with a list of their features and benefits. Table 17 shows the differences between the Wormify composting system and other similar products.

| Urbalive Strengths (+) Weaknesses (-) | Subpod Strengths (+) Weaknesses (-) | VermiGo Strengths (+) Weaknesses (-) | Biovessel Strengths (+) Weaknesses (-) | Wormify Strengths (+) Weaknesses (-) | |

|---|---|---|---|---|---|

| Target Markets | Indoor kit made to compost kitchen bio waste – usually used in households, classrooms, offices (+) | Designed for high and low-volume food waste producers across the globe (+) | Designed for vertical gardening to eliminate home food waste (+) | Meant for beginners that like minimal design and ease of usage (+) | In-garden composting system meant for individual or community use (+) |

| Product | - Self watering feature (+) - Suitable for home application (+) - Red Dot design award (+) - Least functionalities (-) - No in-built sensors (-) | - No smell, no pests (+) - Quick assembly process (+) - Both outdoor and indoor usage (+) - Stable temperature - 9KG composting capacity per week (+) - Compact design (+) | - Activated carbon filter (+) - Collector for vermicompost and nutrient tea (+) - Wall mountable (+) - 3KG processing capacity per (-) - Modular and extendable (+) | - Easy to use (+) - Moisture Sensor (+) - pH Level Sensor (+) - Sprayer (+) - Designed for indoor usage (+) - Odorless (+) | - Compact and modern design (+) - Moisture sensor (+) - Temperature Sensor (+) - pH Level Sensor (+) - Connectivity with phone app (+) - Odorless (+) - 6KG composting capacity per week (+) - Modular and extendable (+) |

| Price | Lowest retail price (-) | Higher retail price (-) | Unknown retail price (?) | High retail price (-) | Unknown retail price (?) |

| Place | Online shop: less advertising, using online retailers | Kickstarter and Indiegogo at the beginning then transitioned to online shop. Dedicated to social media marketing, creating brand awareness and publicity. | Does not sell at the moment – it is in a stage of launching | Same as Subpod | Same as Subpod |

| Promotion | - Active on Instagram but limited to Polish market (-) - Facebook not active (-) | - Facebook and Instagram activity creating brand awareness (+) - Modern website (+) | - Not active on Facebook or Instagram (-) - Website is outdated (-) | - Active on Facebook (+) but not on Instagram (-) - Website is too cluttered (-) | - Modern website is in process of making (+) - Social networks; to target modern farmers (+) |

| (Potential) Competitive Barriers | Inferior product (-) | Superior product (+); not many smart functionalities (-) | Currently a concept and not a physical product yet (-) | Complete product (+); Lots of functionalities (+) | Medium product (-); Community must use it to see its effects (-); Creation of garden community (+) |

4.3 SWOT Analysis

Using a SWOT analysis as a strategic tool brings the whole team together, facilitates involvement in the implementation of the company strategy, and promotes shared awareness of key issues affecting your performance. Creating a SWOT Matrix does not necessitate advanced training and is relatively inexpensive, save for the time of those involved. The acronym SWOT stands for Strengths, Weaknesses, Opportunities, and Threats, and we will use SWOT analysis to evaluate these four facets of the market.

SWOT analysis is presented in Figure 14 for Team Analysis and Figure 15 for product analysis.

4.3.1 Team SWOT Analysis

4.3.2 Product SWOT Analysis

Practical recognition of the SWOT analysis's weaknesses and threats is the first step toward countering them with a comprehensive and innovative collection of strengths and opportunities.

4.4 Strategic Objectives

Strategic goals are statements that suggest what is crucial or essential in your organizational strategy. In other words, they are targets that allow the team to understand their strategic goals and to decide if their plan is successful and well implemented. As a result, we have agreed to use the SMART approach to set targets.

SMART is an acronym that stands for Specific, Measurable, Achievable, Realistic, and Timely. Therefore, a SMART goal incorporates all of these criteria to help focus our efforts and increase the chances of achieving the end goal.

| Letter | Factor |

|---|---|

| S | simple, sensible, significant |

| M | meaning, motivating, memorable |

| A | agreed, attainable |

| R | reasonable, realistic and resourced, results-based |

| T | time-based, time limited, time/cost limited, timely, time-sensitive |

General mission and vision strategic objectives:

Economical strategic objectives:

- To contribute to global ecological economic recovery, a profitable and sustainable method of producing high-quality organic goods, as well as a stable and optimistic agricultural outcome, is to be achieved.

- We want to have a stake in this market by pursuing a strong role in Portugal. We aim to contribute to the national economy by rising the export rate further with each passing day.

Customer/Learning strategic objectives

- Our goal is to educate the public, individuals, companies, and organizations about the benefits of compost and to recycle organic materials from landfills to generate soil for community-based agriculture projects.

- We want to ensure the production of nutritious food healthily to help future generations survive in a healthier world.

- We imagine a world in which government, corporations, families, and individuals work together to sow the seeds of the community so that we can shift our perception of our “waste” stream.

Environmental Strategic objectives

- We envision a world in which everyone disposes of food waste and compostable materials in an environmentally responsible manner, and landfills are never an option.

- We imagine a world in which “waste” is regenerated into living soil, curing the Earth and nourishing our gardens, bodies, and souls.

Transforming Soil. Transforming Lives. Transforming Our Communities.

4.5 Segmentation

To divide properly a broad market into small segments comprising of individuals who have similar needs, requirements, and interests the process called Market Segmentation has to be done. Three main categories are taken into considerations:

- Geographic segmentation

- Demographic segmentation

- Psychographic segmentation

4.5.1 Geographic segmentation

The target market for vermiculture is Southeastern Europe, more precisely – countries that are self-sufficient in terms of agricultural food. According to all economic estimates, the application of vermicompost to grains, fruits, and greenhouse vegetables is more profitable than traditional compost in Turkey conditions [40]. Farmers should consider, however, that the advantages of vermicompost are not only plant-nutritional but that the disease resistance attributed to vermicompost decreases the cost of chemical pesticides as well.

4.5.2 Demographic segmentation

The main factors affecting this part are:

- Income – the citizens whose average monthly salaries are at least at the satisfactory level and actually who live in countries that are favourable for farming.

- Occupation – we assume that the clients whose professions in everyday life are connected with agriculture and farming are more likely to buy a vermiculture system due to their specific job than other consumers.

- Education – greater acceptance of vermicompost by farmers may come with more education and an understanding that sustainable farming also protects the environment.

Variables such as age, gender, religion, or race are not included in the demographic segmentation process since they do not influence the demand for our product.

4.5.3 Psychographic segmentation

Clients may be divided into different groups based on:

- Social class – consumers from the middle and higher class are assumed to be much more interested in the potential purchase of Wormify.

- Lifestyle and personality – clients whose jobs and lifestyles are already deeply connected with agriculture, as well as an awareness that implementing such a system will provide employment opportunities by protecting the environment, augmenting crop production when used as a fertilizer supplement, and assisting in the maintenance of ecological balance.

4.6 Strategy/Positioning

Earthworm and vermicompost markets are expanding, representing a worldwide growth in interest in vermiculture and vermicomposting. Based on our marketing research, we have chosen to concentrate on companies, organizations, and governments all over the world (Business to Business - B2B), with a secondary focus on individuals who want to divert their household waste from the waste stream and recycle it into worm castings on-site (Business to Customer - B2C).